Specification:

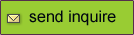

There are 2 producion methods of producing the proflie of thread rolling dies:

- Cutting method: is the traditional way for producing the thread shape of thread rolling dies, the threads are cut by the lathe machine. The thread shapes are with flat tip and flat root.

- Grinding method: is the newly way of producing the thread shape of thread rolling dies, the threads are ground by the thread grinding machines, teh trhead shapes are with round tip and round root.

Why we choose the grinding method for UNIFY thread rolling dies, please check the above for the reason.

Currently, we have more then 10 units of REISHAUER thread grinding machines (Swiss made) in our factory. The thread rolling dies offered by UNIFY are always the grinding type. The higher level quality can be ensured!

Feature:

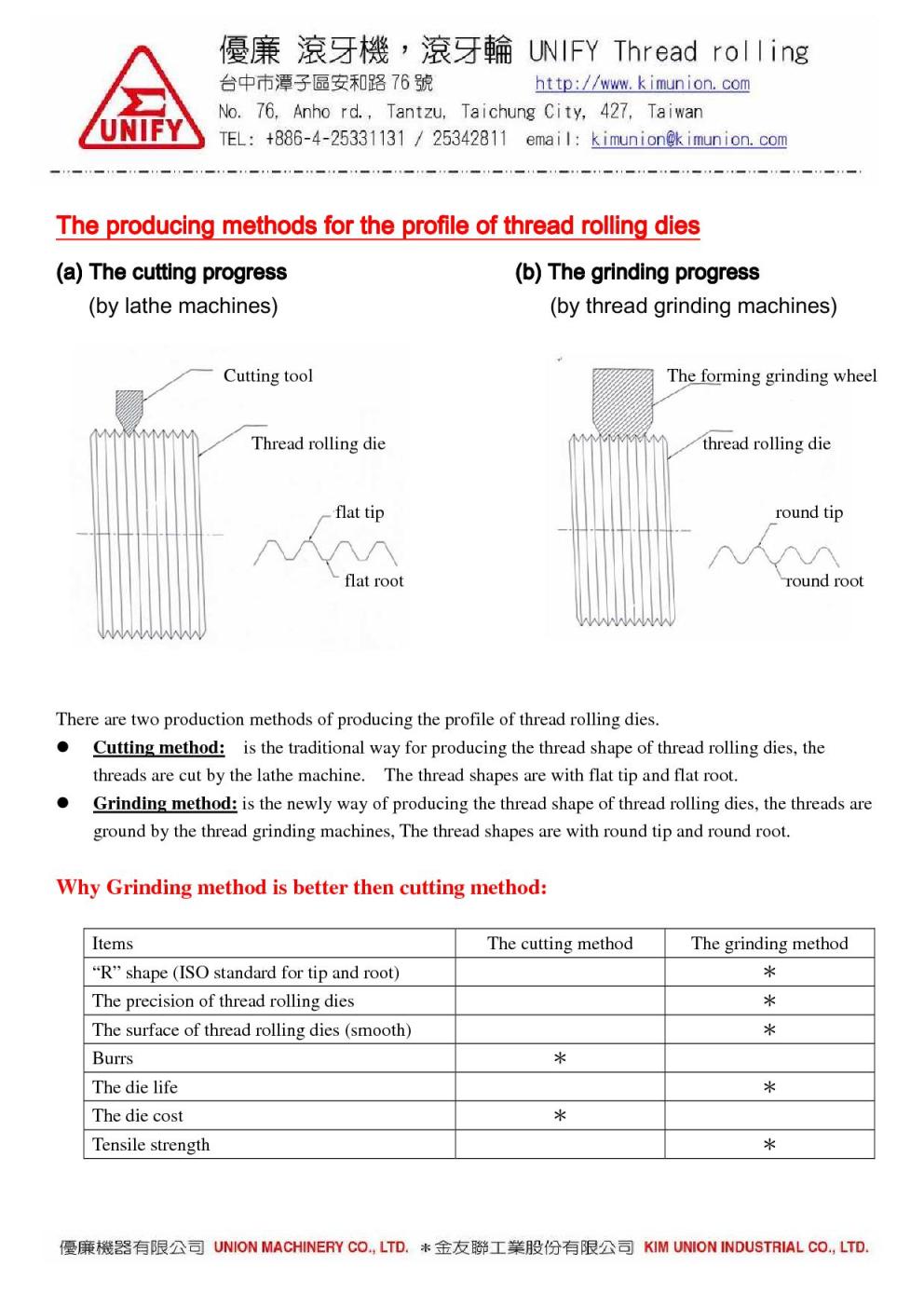

Why Grinding method is better:

| Items | The cutting method | the grinding method |

| "R" shape (ISO standard for tip and root) | * | |

| The precision of thread rolling dies | * | |

| The surface of thread rolling dies (smooth) | * | |

| Burr | * | |

| Die life | * | |

| Die cost | * | |

| Tensile strength | * |